Understanding the intricate language of John Deere Tractor Warning Lights is crucial for operators aiming to maintain their machinery in peak condition while ensuring safety and efficiency during operations. These warning lights, an essential aspect of tractor maintenance, alert users to potential issues within the tractor’s various systems, preventing minor problems from escalating into major malfunctions. This article dives deep into the symbols and meanings behind these vital indicators, providing operators with the knowledge to respond appropriately to various alerts.

Learn Quickly: John Deere Tractor Warning Lights

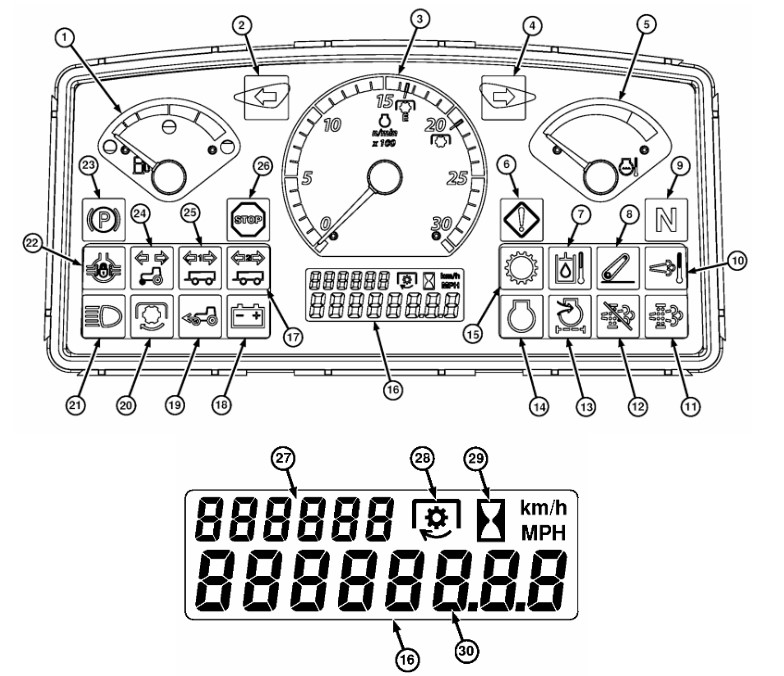

Looking at the image above, you can quickly determine what the numbered image in the table below means.

| Figure # | Gauge/Indicator Light | Description |

|---|---|---|

| 1 | Fuel Level Gauge | Displays the remaining fuel in the tank. |

| 2 | Left Turn Indicator | Activates to signal a left turn. |

| 3 | Tachometer | Shows the engine’s speed in RPM. |

| 4 | Right Turn Indicator | Activates to signal a right turn. |

| 5 | Engine Coolant Temperature Gauge | Shows the temperature of the engine’s coolant. The red zone warns of overheating. Turn off the engine to avoid damage. |

| 6 | Service Alert Indicator | Lights up when there is a system malfunction. |

| 7 | Hydraulic Oil Temperature | Warns when hydraulic oil is too hot. |

| 8 | Electrohydraulic Hitch Indicator | Indicates a hitch system malfunction. |

| 9 | Neutral Indicator | Indicates the neutral position of the transmission reverser. Signals improperly shifting with flashing. |

| 10 | High Exhaust Temperature Indicator | Indicates high temperatures in the exhaust filter for cleaning. |

| 11 | Exhaust Filter Indicator | Signals when the exhaust filter is full of soot and needs cleaning. |

| 12 | Exhaust Filter Disabled Indicator | Indicates the exhaust filter cleaning function is turned off. |

| 13 | Engine Air Cleaner Restriction Indicator | Indicates a clogged air cleaner element. |

| 14 | Engine Information Indicator | Indicates an engine malfunction. |

| 15 | Transmission Information Indicator | Indicates a transmission system malfunction. |

| 16 | Information Display | Shows various vehicle metrics and diagnostic codes. |

| 17 | Trailer 2 Indicator | Flashes with the activation of the trailer’s turn signal or hazard lights. |

| 18 | Charging System Indicator | Indicates an alternator malfunction. |

| 19 | MFWD Engaged Indicator | Lights up when the mechanical front-wheel drive is activated. |

| 20 | PTO Engaged Indicator | Indicates when the rear PTO is activated. |

| 21 | High Beam Indicator | Lights up when the headlights are on high beam. |

| 22 | Differential Lock Indicator | Indicates the engagement of the differential lock. |

| 23 | Park Brake Indicator | Indicates the parking brake is engaged. |

| 24 | Vehicle Indicator | Flashes with the activation of the vehicle’s turn signal or hazard lights. |

| 25 | Trailer 1 Indicator | Flashes with the activation of the trailer’s turn signal or hazard lights. |

| 26 | STOP Indicator | Lights up to signal a severe malfunction. Shut off the engine immediately and check for issues. |

| 27 | Vehicle Information Display | Displays controller fault names in diagnostic mode. |

| 28 | PTO Icon | Indicates the PTO speed setting. |

| 29 | Hour Meter Icon | Indicates when engine hours are displayed. |

| 30 | Vehicle Information Display | Displays wheel speed, engine hours, PTO speed, and diagnostic codes. |

Detailed Definitions: John Deere Tractor Symbols and How to Avoid Them

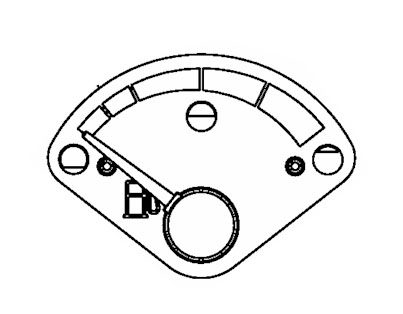

1- Fuel Level Gauge

This gauge is essential for monitoring the tractor’s remaining fuel. It helps the operator manage fuel usage efficiently and plan refills, preventing unexpected stops due to running out of fuel. By monitoring this gauge, operators can ensure that their tractor has enough fuel for the task, optimizing work schedules and reducing downtime.

How to Avoid the Fuel Level Gauge Warning Light

Ensure regular maintenance checks on the fuel sensor and gauge connections to prevent fuel level gauge warnings. If the gauge is inaccurate, inspect the fuel gauge sender unit for damage or wear and replace if necessary. Regular cleaning of the contacts can also prevent issues.

2- Left Turn Indicator

This indicator signals the intention to turn left, enhancing safety on the field and roads. When activated, it alerts other drivers and operators of the tractor’s direction, reducing the risk of accidents. It’s particularly useful in ensuring clear communication of maneuvering intentions in areas with limited visibility or when operating near traffic.

How to Avoid the Left Turn Warning Light

Ensure all bulbs are working and replace any burnt-out. Check the turn signal switch and wiring for faults and repair or replace as necessary to maintain clear signaling.

3- Tachometer

The tachometer measures the engine’s speed in revolutions per minute (RPM) and provides crucial information about its operating condition. By monitoring the RPM, operators can optimize the engine’s performance and fuel efficiency, avoid over-revving, and maintain the engine within safe operational limits, extending its lifespan.

How to Avoid the Tachometer Warning Light

Regularly monitor and maintain the engine to prevent the tachometer from showing incorrect readings. Issues often relate to the vehicle’s electrical system, so ensure all connections are secure and corrosion-free.

4- Right Turn Indicator

Like the left turn indicator, this light signals the intention to turn right. It plays a vital role in communicating with others on the road or in the field, ensuring that all movements are predictable and understood. Thus, it enhances operational safety and prevents collisions.

How to Avoid the Right Turn Warning Light

Like the left turn indicator, maintaining the bulbs and checking the switch and wiring for any damage can prevent issues with the right turn indicator.

5- Engine Coolant Temperature Gauge

This gauge displays the temperature of the engine’s coolant. It is critical for preventing overheating, which can lead to engine damage. The red area warns operators of high temperatures that could indicate problems like a low coolant level, a dirty radiator, or a clogged screen. Immediate action is required to prevent engine damage when high temperatures are predicted.

How to Avoid the Engine Coolant Temperature Gauge Warning Light

To avoid overheating warnings, regularly check the coolant level and ensure the radiator is clean and the coolant system is free from leaks. Also, replace the thermostat if it fails to open, which can cause overheating.

6- Service Alert Indicator

When illuminated, this light indicates a malfunction within the tractor’s systems. It prompts the operator to check the information display for error messages and seek service if necessary. This early warning system helps prevent minor issues from escalating into major problems, ensuring the tractor’s reliability and longevity.

How to Avoid the Service Alert Indicator Warning Light

To prevent malfunctions, your tractor should be regularly serviced. This includes checking all fluid levels and filters and performing recommended maintenance tasks to keep the tractor in good working condition.

7- Hydraulic Oil Temperature

This indicator lights up when the oil exceeds normal temperature ranges, signaling potential overheating. Overheated hydraulic oil can degrade in quality, affecting the hydraulic system’s performance and potentially leading to damage. Monitoring this indicator helps maintain the hydraulic system’s efficiency and prevent operational issues.

How to Avoid the Hydraulic Oil Temperature Warning Light

Check the hydraulic oil level frequently and replace the oil or filter if the system overheats. Ensure that the cooling system for the hydraulic oil is functioning properly to avoid high-temperature warnings.

8- Electrohydraulic Hitch Indicator

This light indicates a malfunction with the tractor’s hitch system. Alerting the operator to check the information display for error messages helps diagnose issues early, ensuring that the hitch system remains functional and reliable for attaching implements and carrying out tasks efficiently.

How to Avoid the Electrohydraulic Hitch Warning Light

Regular inspections and maintenance of the hitch system can prevent malfunctions. Ensure that all electrical connections are secure and that the hydraulic system is free from leaks.

9- Neutral Indicator

It illuminates that the transmission reverser is neutral and flashes to indicate improper shifting. This feedback helps operators ensure the tractor is correctly positioned before starting movement, which is particularly important for safety when starting or stopping the tractor.

How to Avoid the Neutral Indicator Warning Light

To prevent the transmission reverser from showing incorrect neutral signals, check the transmission fluid level regularly and ensure the mechanism is properly adjusted and lubricated.

10- High Exhaust Temperature Indicator

This indicator alerts the operator to high temperatures within the exhaust system, which can occur during active filter cleaning. Understanding when the exhaust temperature is high is crucial for managing the tractor’s operation during these cleaning cycles and ensuring the exhaust system functions correctly.

How to Avoid the High Exhaust Temperature Warning Light

Regularly check the exhaust system for clogs and ensure the filter cleaning process functions correctly. Avoid disabling the exhaust filter cleaning feature unless necessary, and if high temperatures are observed, check for any obstructions in the exhaust system.

11- Exhaust Filter Indicator

This indicator lights up to inform the operator that the soot level in the exhaust filter is high, indicating that a cleaning process is required. Regular exhaust filter cleaning is essential to maintaining the tractor’s efficient operation, preventing clogging, and ensuring emissions remain within regulatory standards. Ignoring this warning can lead to reduced performance and increased fuel consumption.

How to Avoid the Exhaust Filter Warning Light

To prevent the exhaust filter indicator from lighting up, ensure regular driving at operating conditions that allow for passive regeneration. This involves maintaining engine operation at a load factor above 30% for the natural cleaning process to work efficiently. For tractors requiring active regeneration, ensure the tractor operates under the conditions needed for this process to engage, such as applying a load to the tractor for around 20 to 30 minutes to elevate exhaust temperatures and facilitate cleaning.

12- Exhaust Filter Disabled Indicator

When illuminated, this indicator signals that the exhaust filter cleaning function has been manually disabled. While this may be necessary under certain conditions, it’s important to understand that disabling the filter cleaning process can lead to increased soot accumulation, potentially affecting the tractor’s performance and emission control systems.

How to Avoid the Exhaust Filter Disabled Warning Light

To avoid issues with the exhaust filter disabled indicator, do not manually disable the exhaust filter cleaning unless necessary. If disabled, ensure that the system is re-enabled as soon as conditions allow it to maintain proper exhaust filter function and avoid soot buildup, which can lead to reduced performance and increased emissions.

13- Engine Air Cleaner Restriction Indicator

This light warns the operator of a clogged air cleaner element. A clean air intake is crucial for the engine’s performance and longevity. Ignoring this indicator can lead to reduced engine efficiency, increased fuel consumption, and potential engine damage. Regular maintenance or replacement of the air cleaner element is recommended to ensure optimal operation.

How to Avoid the Engine Air Cleaner Restriction Warning Light

Regularly inspect and clean the air cleaner element to prevent blockages. If cleaning does not restore proper airflow, replace the element. Ensuring the air cleaner is functioning efficiently can prevent the restriction indicator from lighting up and maintain optimal engine performance.

14- Engine Information Indicator

This indicator illuminates when there is a malfunction within the engine system. It advises the operator to check the oil level and review error messages on the information display. Prompt attention to engine warnings helps prevent minor issues from becoming major problems, ensuring the engine’s reliability and performance.

How to Avoid the Engine Information Warning Light

Regularly check engine oil levels and quality and ensure timely maintenance, such as oil changes and filter replacements. Address any error messages or faults the engine information system indicates promptly to prevent serious engine damage.

15- Transmission Information Indicator

When this light is on, it indicates a malfunction in the transmission system. The operator should review error messages on the information display and seek service if necessary. Proper transmission maintenance is vital for the tractor’s operational efficiency and for preventing potential breakdowns during critical work periods.

How to Avoid the Transmission Information Warning Light

Maintain the transmission fluid at the correct level and condition. Regular checks and timely fluid changes can prevent transmission issues. If the indicator lights up, inspect the transmission for signs of wear or damage and address any problems immediately.

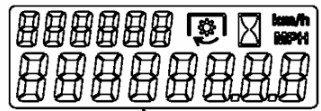

16- Information Display

This digital display provides crucial information about the tractor, including speedometer readings, hour meter, transmission speed selection (if equipped), PTO speed, diagnostic trouble codes, and onboard diagnostics information. It is a central hub for monitoring the tractor’s performance and maintenance needs, helping operators make informed decisions about operating and caring for it.

How to Avoid the Information Display Warning Light

Regularly monitor the information display for any warnings or maintenance reminders. Keeping up with scheduled maintenance and addressing issues early can prevent serious problems and ensure the tractor operates efficiently.

17- Trailer 2 Indicator

This indicator starts flashing when the trailer’s turn signal or hazard warning lights are activated. It helps ensure that signaling is consistent between the tractor and its attached trailer, enhancing safety and communication with other road users or farm personnel during operations.

How to Avoid the Trailer 2 Indicator Warning Light

Ensure all trailer lights, including turn signals and hazard lights, function correctly. Regular checks and prompt replacement of faulty bulbs or repair of wiring issues can prevent this indicator from lighting up.

18- Charging System Indicator

The illumination of this light indicates an alternator or charging system malfunction. Proper functioning of the charging system is essential to keep the battery charged and to ensure the electrical systems of the tractor are powered. If this light comes on, it’s important to investigate and resolve the issue promptly to avoid electrical failures that could impair tractor operation.

How to Avoid the Charging System Warning Light

Regular inspection and maintenance of the tractor’s electrical system, including the alternator and battery, can prevent charging system issues. If the indicator lights up, check the charging system components for wear or damage and replace them as necessary.

19- MFWD Engaged Indicator

This light illuminates when the mechanical front-wheel drive (MFWD) is engaged. This provides enhanced traction and stability, especially in slippery or uneven terrain. It allows the operator to confirm that the MFWD is active, ensuring optimal use of the tractor’s capabilities for various tasks.

How to Avoid the MFWD Engaged Indicator Warning Light

Only engage the mechanical front-wheel drive (MFWD) when necessary to avoid unnecessary wear. Regularly check the MFWD system for proper operation and address any issues promptly to maintain optimal traction and performance.

20- PTO Engaged Indicator

This indicator lights up when the rear Power Take-Off (PTO) is engaged, signaling that the PTO is active and transferring power to attached implements or machinery. Monitoring the PTO status is crucial for safe operation, especially when attaching or detaching implements and during maintenance.

How to Avoid the PTO Engaged Indicator Warning Light

Ensure the PTO is engaged correctly and only when needed. Regular maintenance of the PTO system, including checking for wear and proper lubrication, can prevent issues and ensure that the PTO-engaged indicator functions correctly.

21- High Beam Indicator

This indicator lights up when the tractor’s headlights are switched to a high beam. High beams improve visibility during night operations or in poorly lit conditions. Operators must switch between high and low beams appropriately to ensure their safety and that of other road users.

How to Avoid the High Beam Warning Light

To avoid issues, use high beams only when necessary and switch to low beams when approaching oncoming traffic to prevent dazzling other drivers. To ensure the high beam indicator functions correctly, regularly check the headlight bulbs and replace them if they are faulty.

22- Differential Lock Indicator

When illuminated, this indicator signals that the differential lock is engaged. Engaging the differential lock improves traction by ensuring both wheels on an axle turn at the same speed, particularly useful in slippery or uneven terrain. Operators should use this feature as needed to enhance stability and prevent slippage.

How to Avoid the Differential Lock Indicator Warning Light

Engage the differential lock only to improve traction on slippery or uneven terrain. Disengage it when the condition improves to avoid excessive wear on the drivetrain. Regular maintenance of the differential lock mechanism can prevent issues with the indicator.

23- Park Brake Indicator

This light indicates that the parking brake is engaged, preventing the tractor from moving unintentionally. It serves as a safety reminder to disengage the parking brake before moving the tractor and to engage it when parked to avoid rollaway.

How to Avoid the Park Brake Warning Light

- When parking the tractor, ensure the brake is fully engaged to prevent it from moving.

- Release the parking brake before moving the tractor to avoid straining the engine and drivetrain.

- Regularly inspect the park brake mechanism for wear and adjust it correctly.

24- Vehicle Indicator

This indicator flashes when the tractor’s turn signal or hazard warning lights are activated, signaling turns or alerting to potential hazards. It’s essential for communicating the operator’s intentions to others nearby, enhancing safety during operation on farms, roads, or any other area where visibility and clear signaling are crucial.

How to Avoid the Vehicle Indicator Warning Light

This light functions correctly when the tractor’s turn signals or hazard lights are operational. Regularly check the lights and replace any faulty bulbs. Ensure wiring and fuse related to the turn signal and hazard lights are in good condition.

25- Trailer 1 Indicator

Like the Trailer 2 Indicator, this light flashes when the first trailer’s turn signals or hazard lights are activated. This ensures that the tractor and all attached trailers are synchronized in signaling, improving safety and communication during transport or field operations.

How to Avoid the Trailer 1 Indicator Warning Light

Like the vehicle indicator, ensure the trailer’s lighting system is correctly connected and functioning. Regular maintenance of the trailer’s lighting and electrical connections can prevent issues with this indicator.

26- STOP Indicator

This critical indicator illuminates to warn of a serious malfunction requiring immediate attention. Operators should stop the engine immediately and investigate the cause, checking the information displayed for error messages. Prompt action may prevent further damage and ensure safety.

How to Avoid the STOP Indicator Warning Light

This critical indicator signals a severe malfunction. Regularly check the tractor’s systems and promptly address any error messages. Ensure the tractor is serviced according to the manufacturer’s schedule to prevent issues that could trigger this indicator.

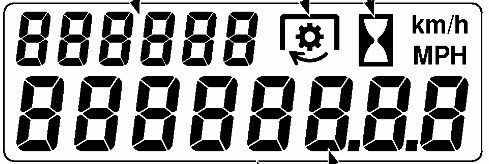

27- Vehicle Information Display

This display shows critical vehicle information, such as gear selection for models with Hi/Lo transmission settings. When in diagnostic mode, it provides:

- Detailed fault information

- Identifying specific issues with the tractor’s systems

- Allowing for more targeted troubleshooting and maintenance

How to Avoid the Vehicle Information Display Warning Light

Monitor the display regularly for warnings or maintenance reminders. Keeping up with scheduled maintenance and addressing issues early can prevent serious problems and ensure the tractor operates efficiently.

28- PTO Icon

This icon illuminates when a specific PTO speed is selected, indicating that the tractor is ready to drive implements at the chosen speed. Monitoring the PTO status is crucial for effectively using attached machinery, ensuring that operations are carried out at the correct speed for optimal performance and safety.

How to Avoid the PTO Icon Warning Light

Ensure the PTO is engaged correctly and only when needed. Regular maintenance of the PTO system, including checking for wear and proper lubrication, can prevent issues and ensure the PTO-engaged indicator functions correctly.

29-Hour Meter Icon

This icon shows when the tractor’s engine hours are displayed on the Vehicle Information Display. Engine hours provide a measure of total operating time. Tracking engine hours is important for scheduling regular maintenance and ensuring the tractor is kept in optimal condition.

How to Avoid the Hour Meter Icon Warning Light

Monitor engine hours to keep track of maintenance intervals. Adhering to a regular maintenance schedule based on engine hours can prevent issues that might otherwise trigger warning indicators.

30- Vehicle Information Display

This comprehensive display provides information on the tractor’s wheel speed, engine hours, PTO speed, and diagnostic codes. It is the central point for monitoring the tractor’s performance and maintenance needs, helping operators manage their equipment effectively and efficiently.

How to Avoid the Vehicle Information Display Warning Light

Keep the information displayed in good working order by addressing any faults indicated. Regularly updating the tractor’s software, if applicable, and ensuring the display is clean and legible can help prevent issues with this system.

FAQs About John Deere Tractor Symbols and Meanings

Some of the John Deere Tractor Symbols are of critical importance. In light of these 5 important warnings, you may want to look at the most common problems and their solutions.

What does the Fuel Level Gauge warning light indicate?

It signals that the tractor’s fuel is running low and needs refilling soon to prevent unexpected stops.

Why would the Engine Coolant Temperature Gauge warning light come on?

This light warns of engine overheating, indicating that the engine must be shut off immediately to avoid damage.

What triggers the Service Alert Indicator warning light?

It illuminates to indicate a system malfunction, advising the operator to check for error messages or seek service.

How can I prevent the Hydraulic Oil Temperature warning light from coming on?

Regularly check and maintain the hydraulic oil level and quality, ensuring the cooling system functions properly.

What does the STOP Indicator warning light signify?

This critical light signals a severe malfunction, necessitating an immediate engine shutdown to check for issues.

Final Thoughts

Navigating through John Deere Tractor Warning Lights is a skill every operator should possess. This article has explored the meanings behind these crucial indicators, offering insights into maintaining your tractor’s performance and ensuring operational safety. From understanding when your tractor is signaling a low fuel level to recognizing the critical alerts that require immediate action, operators are now equipped with the knowledge to respond effectively to warning lights, ensuring both the longevity of their machinery and the safety of their operations.

Was this page helpful?

Similar Problems in Other Models

Is the Nissan Pathfinder 4WD Warning Light on?

International Truck Dashboard Symbols And Meanings

JCB Loader Dashboard Warning Lights And Symbols

Heavy Equipment Caterpillar Warning Symbols and Meanings

Chrysler Auto Start Stop Warning Light (Causes and Solutions)

Car News and Reviews

Would you like to take a look at the car news and reviews we have carefully selected and published for you?

2024 Lucid Air Prices Go Down

GM's Big Road Network for Hands-Free Driving

DTC C0561-71 Vacuum Sensor Code on GM, GMC and Chevy

C1201 Code Toyota and Lexus (Causes and Solutions)

Chrysler Auto Start Stop Warning Light (Causes and Solutions)

2024 Ford Mustang GT: Digital Age Meets Classic Power

The 2024 Chevrolet Silverado 2500HD ZR2: An Off-Road Marvel

2024 Chevy Colorado ZR2 Bison: The Ultimate Off-Road Experience

The 2024 Lucid Air Sapphire Track Drive Experience

2024 Subaru Forester Review, Specs, Price, Release Date